Category Archive: Uncategorized

At ABL Electronics, we design and develop robotic wire and cabling solutions and ground straps for complex commercial and industrial systems. For over 45 years, our team of engineering and production specialists offer production services, including cutting, re-spooling, tinning, twisting, and more. Our services are available as custom solutions for a wide variety of electronic systems, including robotics. Today’s robotic systems require robust, high-performance electrical wires and cables for reliable performance in adverse and busy conditions. Learn more about our production capabilities, services, and experience in the robotics industry.

Considerations

When you’re completing a robotics project for any industry, having the correct wiring and cable resources is essential. Some of the key factors that determine which wiring products are the right fit for your project include:

- The number of cycles the system requires

- The degree and type of movement the wire or cabling will need to complete

- Electrical factors such as the voltage requirements

- Wiring protections such as EMI shielding, materials with appropriate flammability characteristics, and more

- The environmental factors of the space the robotics system or wiring will perform in, including its temperature, likelihood of abrasion, humidity, and presence of fluids

Identifying these factors can ensure your wiring and cable products have the right protective and performance characteristics for the job.

Electronics Capabilities for the Robotics and Military/Defense Industry

At ABL Electronics, we serve clients across multiple different industries with wire processing and production services as part of our custom solutions offering. Two of our markets are robotics and the military/defense industry.

Our wiring and cable products include:

- High Flex Cable: This cable offers a greater degree of flexibility for continuous and repeated flexing cycles. High flex cables are built for vigorous, high-performance conditions.

- Continuous Flex Cable: Continuous flex cabling solutions can flex and bend continuously as part of robotics, gantries, and other continually moving systems. These cables can roll, flex, and bend in fixed or variable patterns throughout long lifespans of multiple-use cycles.

- Control and Instrumentation Cable: These specialized cables are built to monitor or control electronic robotics and systems that use low-power but complex signals.

- Wire Harness: Wire harnesses are configurations that organize and manage multiple different wires within one specific bundle. They can be customized to fit the performance needs and space requirements of different electronics systems for easier configuration, maintenance, and routing.

- Cable Assembly: Similar to wire harness configurations, robotic cable assemblies organize and protect groups of wires and cables in harsher environments. Its heavy-duty shielding material makes cable assemblies ideal for extreme applications.

Military and Defense Applications

Military and defense operations increasingly incorporate unmanned vehicles for handling dangerous or remote tasks without direct human operation. ABL Electronics’ product team provides wiring solutions for increased unmanned vehicles usage for military and defense applications.

Miniature Wires

Miniature wiring solutions are used in military robotics to manufacture devices that can withstand the extreme circumstances encountered in military environments. Small but robust and flexible wiring products for robotics allow for more innovation, unique applications, and the development of advanced tools.

Applications

Our team specializes in robotics, and our wiring and cabling solutions are built for these applications:

- Branch wires and connectors

- Control panel feeds and connectors

- Dress packs

- Electrical raceways

- Feeder wires and connectors

- Flexible raceways

- Fiber optic and cable conduits

- Switchbox wires and connectors

- Work cells

High-Quality Electronics from ABL Electronics Power the Robotics Industry

Choose ABL Electronics for completely customized robotic cable and wiring solutions for your robotics project. Contact us today to learn more about our capabilities and process or to request a quote and start your order.

ABL Electronic Supplies, Inc. provides customers with top-quality wire, cable, and other related products with efficient delivery and at some of the most competitive prices on the market. In addition, we provide a selection of services to meet our customers’ needs, including cut and strip services.

What Is Cut and Strip?

Before installation, wires and cables must be prepared for use. This process involves unspooling and cutting the wire from the reel and stripping back a portion of the insulation. Cut and stripped wire consists of finished wire that’s properly packaged and prepared for assembly, along with wire that’s partially stripped and ready for installation.

By cutting and stripping wire products, companies can save more money on excess wire materials and simplify the manufacturing process.

Types of Wire Cutting and Stripping/Capabilities

At ABL Electronic Supplies, Inc., we offer precision cutting and stripping services using some of the most reliable equipment for cutting and stripping wires. Through these services, we provide customers with high-quality stripped wire or stripped cable products that make manufacturing processes more cost-effective and efficient. We’ll cut wires to a designated length and remove insulation to our customers’ specifications.

Depending on our customers’ needs, we provide the following cutting and stripping services:

- Full or partial strip left and right

- Cut to length

- Multi-layer with shield processing

- Multi-conductor cable jacket stripping

- Jacket and inner conductor stripping

And including but not limited to projects utilizing the following types of wire:

- UL 1007/1569

- Medium Wall

- UL 1015/1230

- Heavy Wall

- Awg Sizes: 14 awg-22 awg

- Tinned Copper, PVC Insulation, Strip Options: 1/8”- 3/4″

- Cut & Strip Projects for electronic circuits and internal wiring of electronic and electrical equipment

- Resistant to:

- Oils

- Acids

- Alkalis

- Flame

- Moisture

- Fungus

Benefits

Cut and strip services offer many benefits for businesses, depending on the requirements of their application. These advantages include the following:

Complete Separation

Wire stripping equipment strips insulation from the wire’s metal core, unlike other machinery that crushes the wiring together and separates them later. This process helps make sure a plastic cover isn’t present on the wire. The removal of plastic helps improve the metal grade’s recycling rate and usability. However, the wire must be straight and devoid of knots to undergo stripping.

Environmental Protection

The cutting and stripping process is also more environmentally friendly compared to other processes. This is because the stripping machinery doesn’t require the use of any chemicals or water throughout the stripping process to apply mechanical force. Additionally, the equipment doesn’t produce any dust. As a result, this process doesn’t consume large amounts of resources and doesn’t generate any pollution.

Easy Operation and Reduced Labor

Generally, cut and strip equipment only requires a single operator to run it, which reduces labor costs. Cutting and stripping machinery has a simple structure, making it easy to use and incorporate into manufacturing processes.

Cut and Strip Services from ABL Electronic Supplies, Inc.

Based on your individual needs, the experts at ABL Electronic Supplies, Inc. will provide cut and strip services to your specifications. We use reliable cut and strip systems to complete this process and provide you with top-quality end products with each service. Regardless of what you require, we’ll work to provide you with everything you need at affordable prices.

In addition to cut and strip services, we offer cut and coil, cut pieces, dyeing, respooling, striping, tinning, and twisting services to meet your wire product needs. We also carry a selection of products, including a range of braids, cables, cable ties, tubing, cords, and more.

If you would like to find out more about our cut and strip capabilities or other services or products we offer, contact us today to submit a message or quote request.

What Does AWG Mean?

Have you ever wondered what AWG is? The term, which stands for American Wire Gauge, is a system used to convey the standard size of single-strand, solid, round, electrically conductive wires in North America. The system was created in the mid-nineteenth century as a replacement so that people could rely on one standard instead of various measurements by different manufacturers.

The Basics of AWG

Here’s more information about the various wire gauges and current limits:

AWG Wire Sizes

The number can help people determine a wire’s current-carrying rating by using the formula D(AWG)=.005·92((36-AWG)/39) inch. Although the system acknowledges a wire’s resistance level, the size of its protective insulation is not taken into consideration. A wire gauge refers to how a wire is constructed and its electrical resistance. Thicker wires have a lower resistance and gauge number because there are more electrons surging through it. Meanwhile, thin wires can’t carry as many electrons and have a higher gauge number and resistance level. The smallest standard size or gauge in the AWG system is 40 and 0000 AWG is considered the largest. The wires double in size every 6 steps in gauge.

Metric Wire Gauges

The Metric Gauge scale is the opposite of the AWG system, in that the diameter goes down as the gauge increases. This means that a wire that measures 2 mm in diameter would be considered 20 gauges. To prevent confusion or potential mix-ups, metric wire gauges are usually specified in millimeters instead of metric gauges.

Load-Carrying Capacities

A load-carrying capacity refers to the capacity of a wire to carry a current or transmit amps. Several factors, including the wire’s thickness, thermal conductivity, insulation temperature limit, voltage drop, and outside elements, such as the temperature and air convection, are used to calculate it. There are currently two maximum amps: one is for a more conservative power transmission that uses 700 circular mils per amp rule, while the other is for chassis wiring in the air.

Maximum Frequency for 100% Skin Depth

The maximum frequency for 100% skin depth is used in high frequency AC engineering when a wire’s current happens to flow along the outside of the wire as well. When the calculated skin depth reaches the equivalent of the radius of the wire, anything above this frequency could burn or harm someone’s skin.

Why Is AWG Important?

AWG is important because it can help people identify which electrical wires and extension cords they should use in their home or business. Without this clarification, they could get the wrong AWG cable and it could overheat and possibly become a fire hazard because it did not have the correct current-carrying capacity.

Request a Customized Quote From ABL Electronic Supplies, Inc.

ABL Electronic Supplies has provided quality products at competitive prices to our trusted partners for almost half a century. We are proud to offer a range of grounding products, including cables, cable ties, ground straps, wires, and more. A vast array of industries, ranging from the military to aerospace, solar, and transportation, trust our products.

To learn more about why you should partner with ABL Electronic Supplies, contact us today. One of our team members would be happy to speak with you and provide a free customized quote.

(Click to Expand)

The COVID-19 pandemic severely impacted the supply chain, leading to shortages and delays in nearly every industry and across numerous products including ground straps, wires, cables, and more. Adapting to these changes in a post-COVID world will be essential for businesses to survive and thrive. Here, ABL Electronic Supplies explains the coronavirus supply chain and how you can stay resilient with your operations after the pandemic.

Supply Chains Post-COVID

Over the years, supply chains have been carefully streamlined to save time and money. This has created a system with no built-in buffers to account for delays or other disruptions, which was fine—until it wasn’t. COVID-19 highlighted the incredible delicacy of this system, a delicacy many companies weren’t aware of until it started to impact their production, sales, and bottom line.

China has long served as the “world’s factory,” and companies that rely on products and materials from China are especially vulnerable. The pandemic wake-up call and their experience with the coronavirus supply chain has made many of them rethink the way they do business to avoid these types of disruptions in the future.

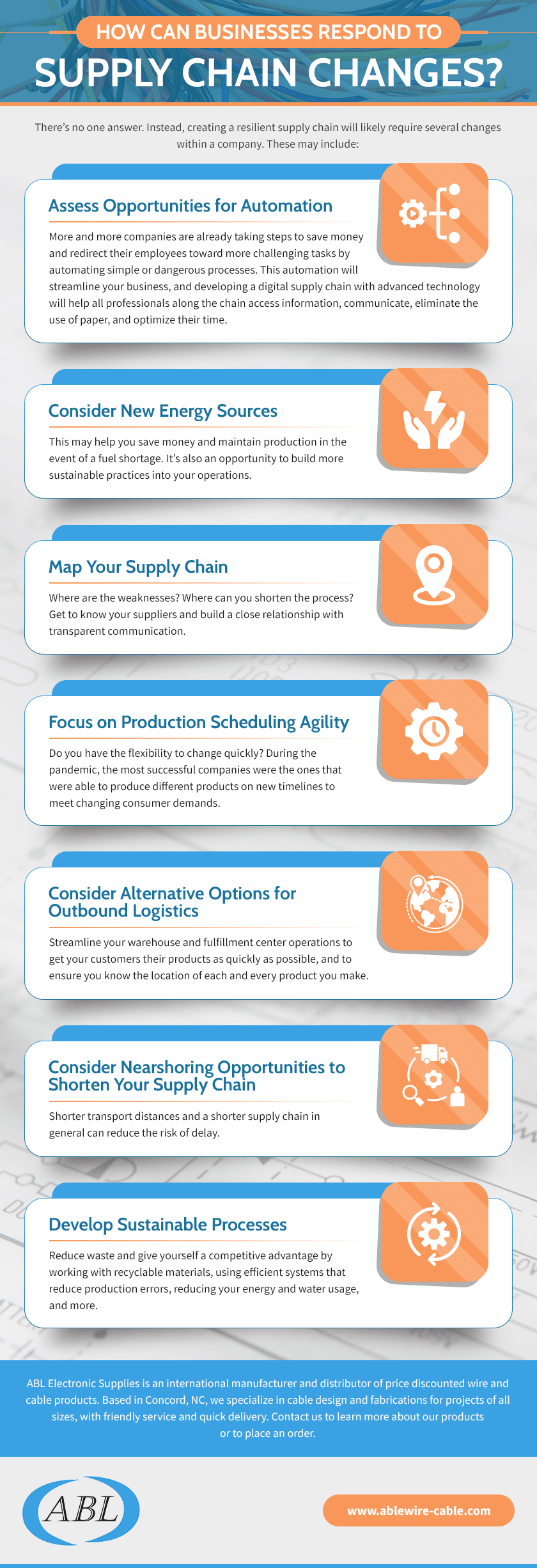

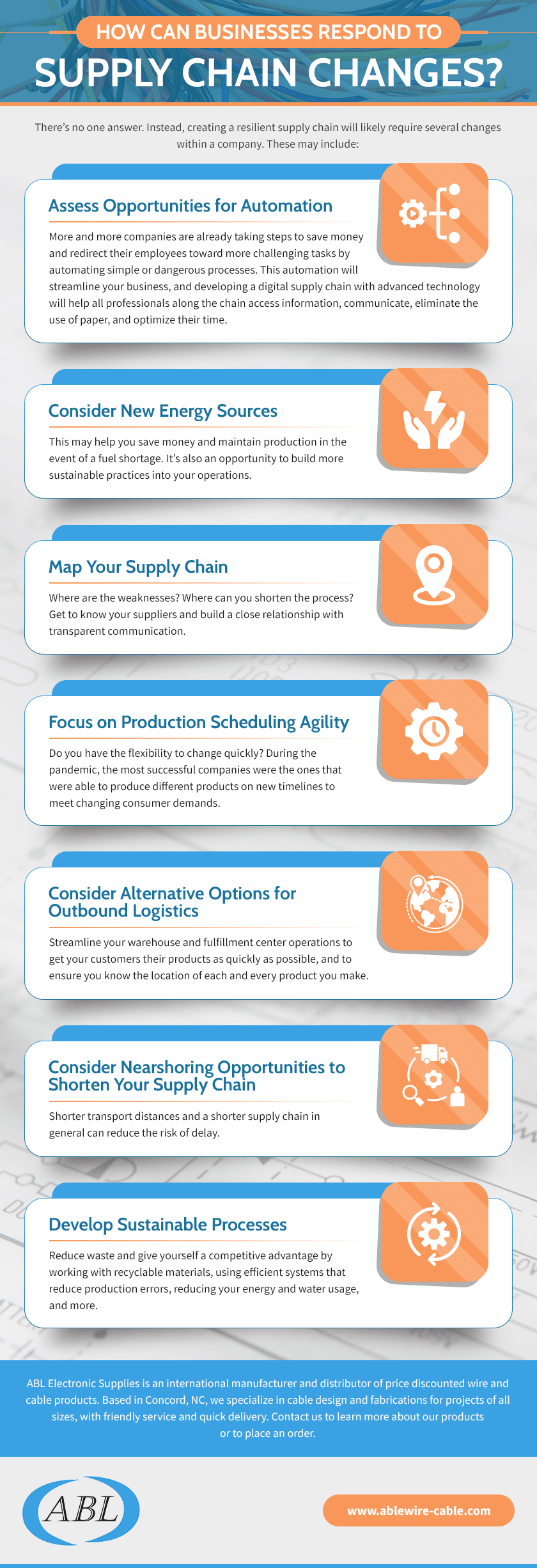

How Can Businesses Respond to Coronavirus Supply Chain Changes?

There’s no one answer. Instead, creating a resilient supply chain will likely require several changes within a company. These may include:

- Assess opportunities for automation: More and more companies are already taking steps to save money and redirect their employees toward more challenging tasks by automating simple or dangerous processes. This automation will streamline your business, and developing a digital supply chain with advanced technology will help all professionals along the chain access information, communicate, eliminate the use of paper, and optimize their time.

- Consider new energy sources: This may help you save money and maintain production in the event of a fuel shortage. It’s also an opportunity to build more sustainable practices into your operations.

- Map your supply chain: Where are the weaknesses? Where can you shorten the process? Get to know your suppliers and build a close relationship with transparent communication.

- Focus on production scheduling agility: Do you have the flexibility to change quickly? During the pandemic, the most successful companies were the ones that were able to produce different products on new timelines to meet changing consumer demands.

- Consider alternative options for outbound logistics: Streamline your warehouse and fulfillment center operations to get your customers their products as quickly as possible, and to ensure you know the location of each and every product you make.

- Consider nearshoring opportunities to shorten your supply chain: Shorter transport distances and a shorter supply chain in general can reduce the risk of delay.

- Develop sustainable processes: Reduce waste and give yourself a competitive advantage by working with recyclable materials, using efficient systems that reduce production errors, reducing your energy and water usage, and more.

The copper supply chain faces many of the same disruptions, and what we’re seeing now is a raw materials shortage, increase in demand, and rising prices. Copper has reached its highest price in years, and it continues to rise along with silver, gold, and plastic resin. Stock shortages and long lead times are becoming the norm. An item that used to take four to six weeks can take 10 or even 20.

Until the system finds balance, companies have to be prepared to work within this framework. This is how to get ready, so you can meet your wire and cable needs:

- Place orders now. Prices will continue to rise and factory lead times will extend even further. If you’re waiting for both of those factors to drop, you’ll be waiting a long time.

- Lock in your prices. Build a relationship with your supplier and work with your sales representative to guarantee an affordable price and a steady supply. Make sure they understand your future projects and needs.

- Protect your stock. It will become more valuable as the cost of precious metals goes up, and you don’t want to lose what you have to carelessness, production error, or even theft.

Building supply chain resilience is an overdue necessity. It will help your business save time and money even in the best of times, and it will ensure you’re as prepared as possible to withstand another global catastrophe.

ABL Electronic Supplies is an international manufacturer and distributor of price discounted wire and cable products. Based in Concord, NC, we specialize in cable design and fabrications for projects of all sizes, with friendly service and quick delivery. Contact us to learn more about our products or to place an order.

Ground instruments are anti-static devices designed to protect people and electronic equipment from electrostatic discharge (ESD). They create a designated path through which electrical current can flow to a safe ground without harming people or damaging equipment.

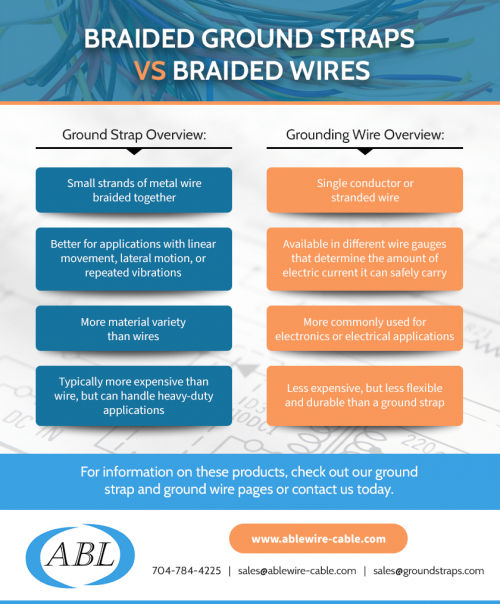

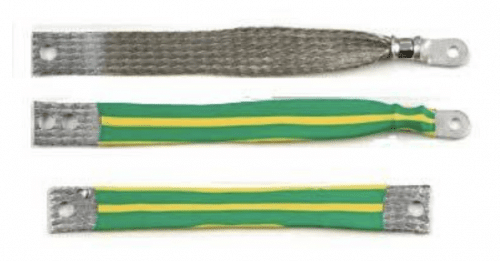

These critical safety devices are available in many variations. For example, they can be made from aluminum, copper, stainless steel, and plated materials, shaped into flat, tube, or specialized forms, and designed as straps, strips, or wires. Each variant offers distinct advantages and disadvantages that make them suitable for different applications. Below, we highlight braided ground straps and ground wires, but visit our blog to learn more about ground straps at an overview level.

Overview of Braided Ground Straps

Braided ground straps are manufactured by braiding multiple wires together and terminating them with metal connectors. This durable design makes them well-suited for use in highly demanding applications and environments. Additionally, since they have a large surface area, they benefit from the skin effect (i.e., current flows on the outside of the conductive material), making them ideal for low impedance RF ground connections. However, since they are prone to retaining water, which can lead to corrosion, they are not appropriate for situations where they will regularly come into contact with water. As such, they should not be used buried directly.

Braided ground straps are manufactured by braiding multiple wires together and terminating them with metal connectors. This durable design makes them well-suited for use in highly demanding applications and environments. Additionally, since they have a large surface area, they benefit from the skin effect (i.e., current flows on the outside of the conductive material), making them ideal for low impedance RF ground connections. However, since they are prone to retaining water, which can lead to corrosion, they are not appropriate for situations where they will regularly come into contact with water. As such, they should not be used buried directly.

Examples of typical applications for braided ground straps include:

- Grounding one radio chassis to another

- Grounding equipment to a single-point ground

- Bonding swinging gates/doors to a ground system

Overview of Ground Wires

Ground wires are available in solid and stranded versions. Solid ground wires consist of a single solid wire, while stranded ground wires consist of multiple wires stranded together. The wires are typically made from copper due to the material’s conductivity and durability. This simple design makes this type of anti-static device easy to install and connect. Additionally, it is available in insulated variations, which enables it to be used safely in outdoor environments. However, since it is round, it has less surface area, making it unsuitable for low impedance RF ground connections.

Ground wires are available in solid and stranded versions. Solid ground wires consist of a single solid wire, while stranded ground wires consist of multiple wires stranded together. The wires are typically made from copper due to the material’s conductivity and durability. This simple design makes this type of anti-static device easy to install and connect. Additionally, it is available in insulated variations, which enables it to be used safely in outdoor environments. However, since it is round, it has less surface area, making it unsuitable for low impedance RF ground connections.

Examples of typical applications for ground wires include:

- Basic grounding of amateur radio equipment (typically solid wires that are 10 AWG)

- Basic lighting protection grounds (typically stranded wires that are 2 AWG and up)

Quality Ground Products at ABL Electronic Supplies

Ground instruments play a critical role in protecting people and products in electrical applications. That’s why it is important to purchase them from a supplier you can trust, such as ABL Electronic Supplies.

At ABL Electronic Supplies, Inc., we offer made-to-order ground straps and wires. Each one we deliver is made to the highest quality using state-of-the-art equipment, so our customers can rely on them to protect their employees and equipment. For information on these products, check out our ground strap and ground wire pages or contact us today.

Electrical devices and systems are an important part of day-to-day operations in the industrial, commercial, and residential sectors. However, while they make our lives easier in many ways, they also pose a health and safety risk. Any electrical equipment can experience short circuits or surges, which can cause an electrical current discharge to pass through anyone working on the device or system, resulting in injury or, in severe cases, death. Ground straps are key to preventing these injuries and fatalities.

What Is a Ground Strap?

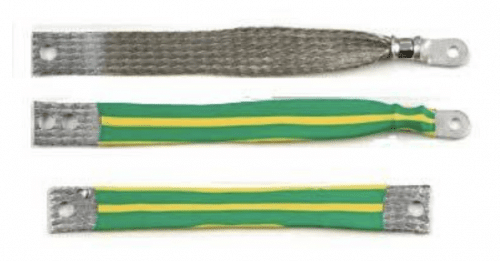

Ground straps—also known as grounding straps—play a vital role in ensuring the safety of electrical devices and systems. The ribbon-like components connect to the equipment and a safe ground. In the event of a short circuit or surge, they serve as a designated path through which electricity can flow without causing harm to people or damage to other equipment.

Types of Ground Straps

Ground straps come in many variations to suit different applications. Three of the key design factors to keep in mind when choosing one are strap type, strap shape, and conductor material.

Strap Type

There are numerous types of ground straps available, including:

- Braided. Braided ground straps are made by interlacing a single wire or multiple wires.

- Mesh/Grid. Wire mesh/grid ground straps are made of cloth-like material formed by weaving or welding wires together.

- Sheet/Strip. Ground sheets or strips are flat and rectangular.

- Solid. Solid ground straps are made from one solid wire.

Strap Shape

Ground straps are generally flat or tubular. However, some manufacturers can make them specialized shapes.

Conductor Material

Typical materials for ground straps include:

- Aluminum

- Copper

- Tinned Copper

- Stainless Steel

- Nickel-Plated Materials

- Silver-Plated Materials

Industrial Applications of Ground Straps

Ground straps are employed alongside electrical devices and systems across a wide range of industries. Some of the equipment for which it is commonly used include:

- Aircraft

- Electrical Panel Doors and Enclosures

- Electronics

- Engines and Motors

- Locomotives

- Machinery and Heavy Equipment

- Power Supplies

- Transformers

- Vehicles

Quality Ground Straps at ABL Electronic Supplies

Ground straps are essential to ensuring the safety of employees and other equipment when using electrical devices and systems. Given this important function, it is important to choose quality ground straps from a reliable supplier. Otherwise, you risk employee injury and equipment damage.

If you need ground straps for your facility and operations, the wire and cable experts at ABL Electronic Supplies are here to help! We offer grounding straps that you can count on to protect your employees and equipment. For more information on our products or assistance choosing one for your needs, contact us today.